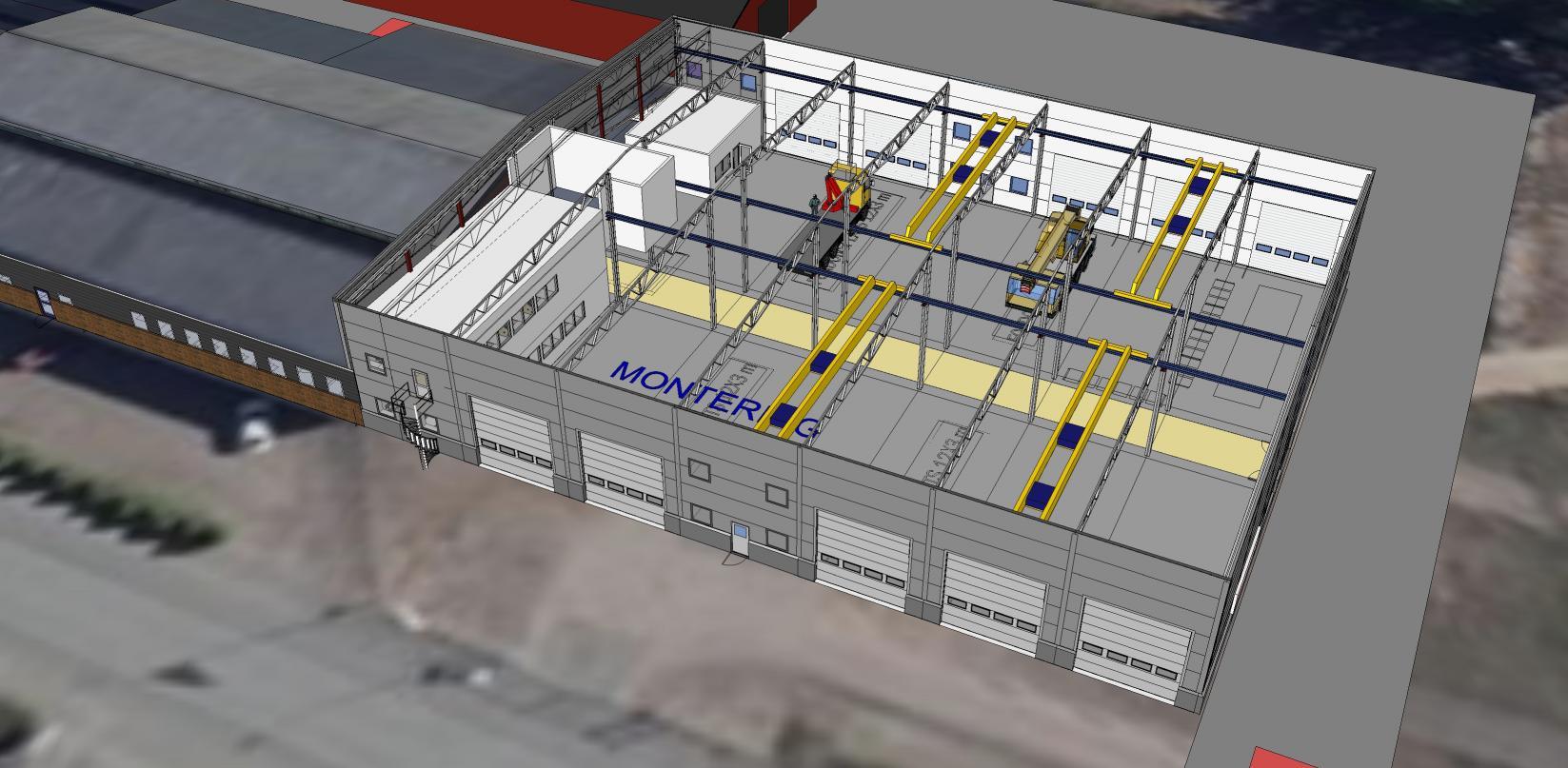

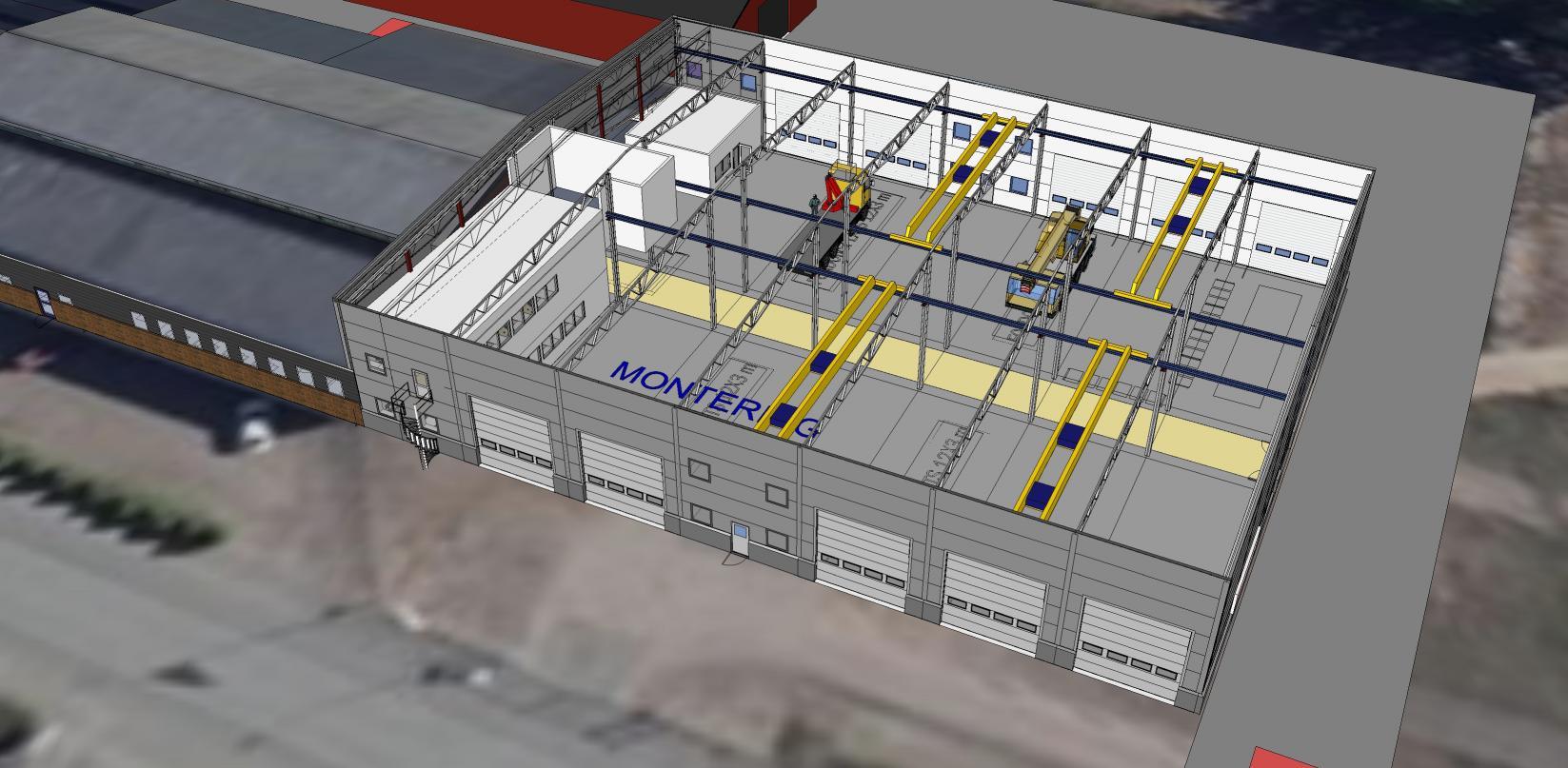

Goldschmidt is strengthening its road-rail vehicle field with an extensive site expansion in Sweden. Within a set construction period of 2,5 years, the production site in Osby will be modernized and expanded with a new 1,700 m² vehicle assembly hall.

The investment project is an important milestone for Goldschmidt Sweden AB, a specialist in road-rail vehicles and part of the international Goldschmidt Group. The project includes the refurbishment of existing production halls and the construction of a new, state-of-the-art assembly hall, enhancing production capacity, efficiency, and working conditions.

Construction company Rickardsson Bygg AB has recently been commissioned to carry out the first phase of the project, the construction of the new vehicle assembly hall, scheduled for completion by the end of 2026.

“This investment is a clear commitment to the Osby site and to the long-term development of Goldschmidt Sweden,” says Stefan Magnusson, Managing Director of Goldschmidt Sweden. “By modernizing our facilities, we are not only creating optimal production conditions but also significantly improving the working environment for our employees.”

Alongside the new infrastructure, the project focuses strongly on sustainability. Energy-efficient upgrades—including new windows, improved insulation, and connection to the local district heating network—will significantly reduce the site’s carbon footprint.

Dr.-Ing. Georg Friberg, CEO of the Goldschmidt Group, emphasizes the strategic importance of the project: “The investment in our Swedish site and in the road-rail vehicle segment is a vital part of our global growth strategy. With cutting-edge production facilities, we can meet the growing demands of our customers even more effectively and further expand our market position.”

Karl Goldschmidt, Chairman of the Supervisory Board and member of the Goldschmidt family, adds: “As a family-owned company, we think in generations. With this forward-looking investment, we are ensuring that Goldschmidt Sweden remains a strong and sustainable production site for decades to come.”